PROFILE

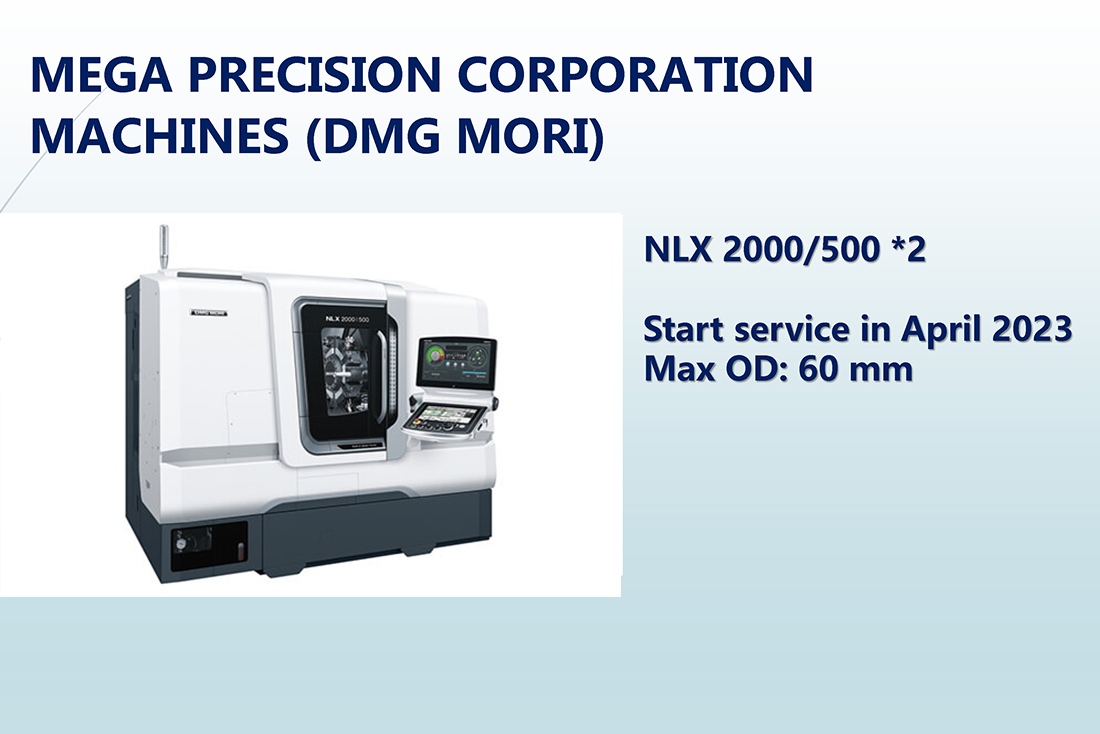

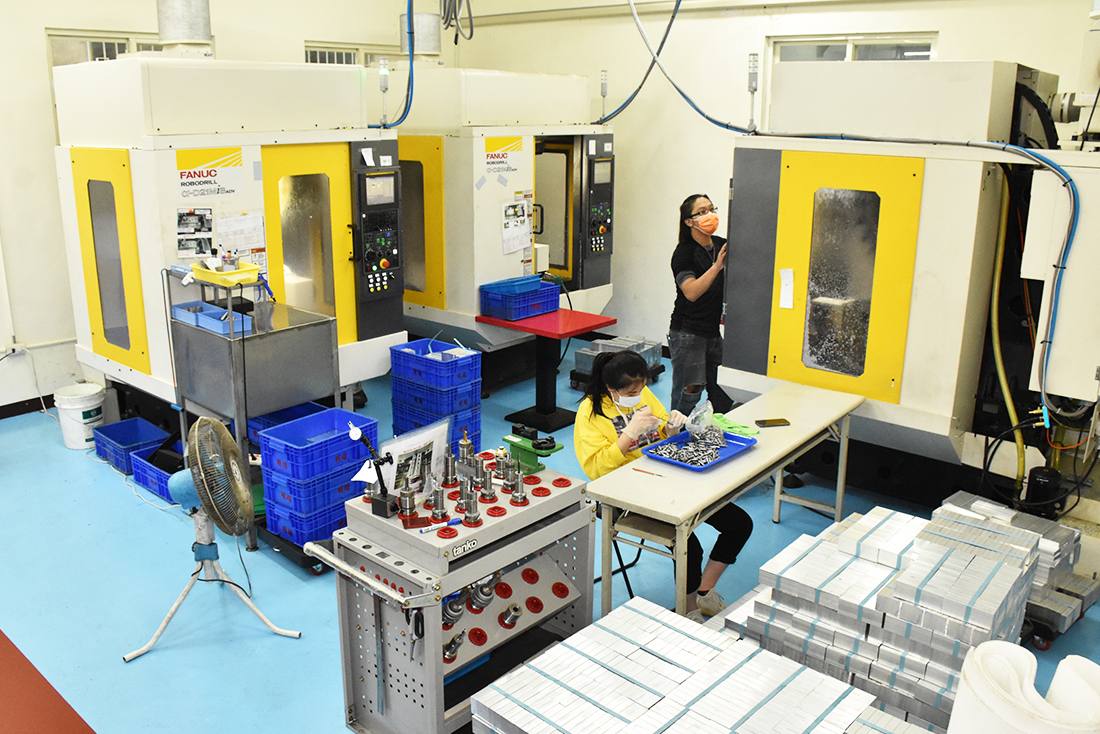

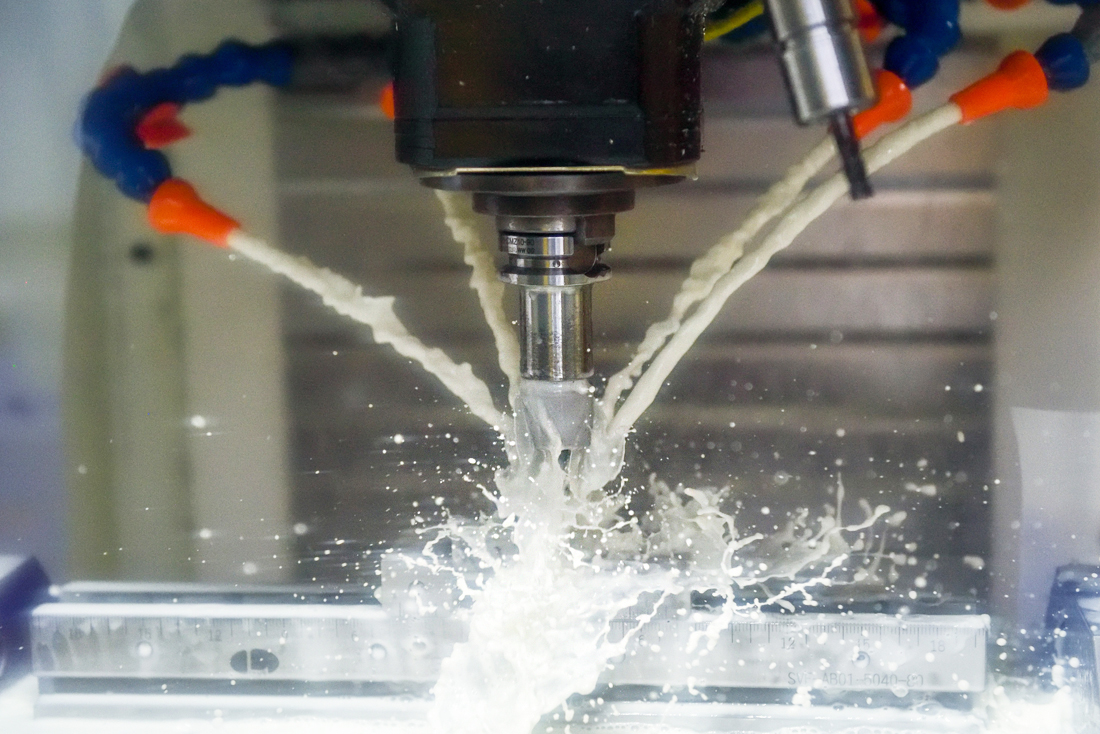

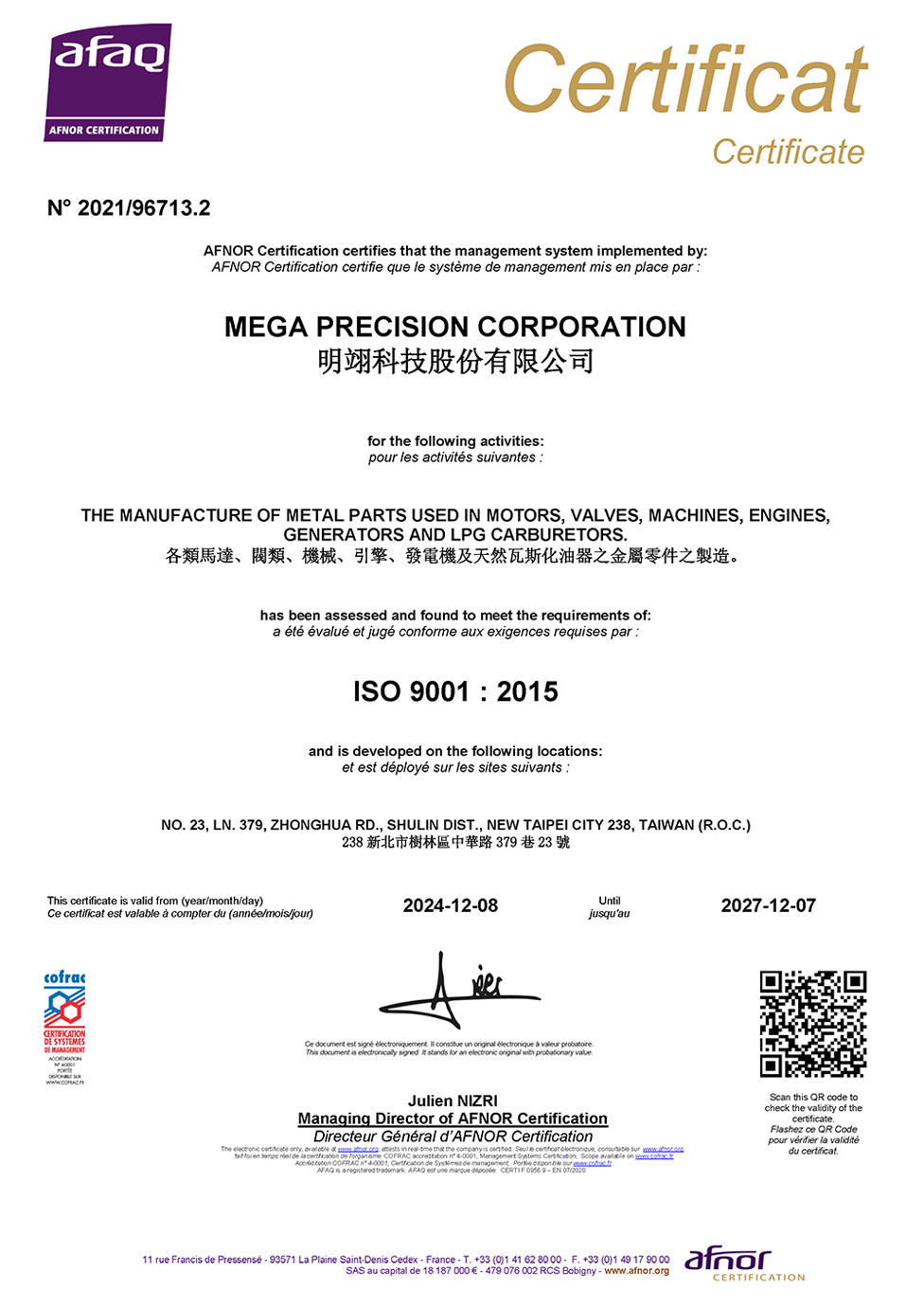

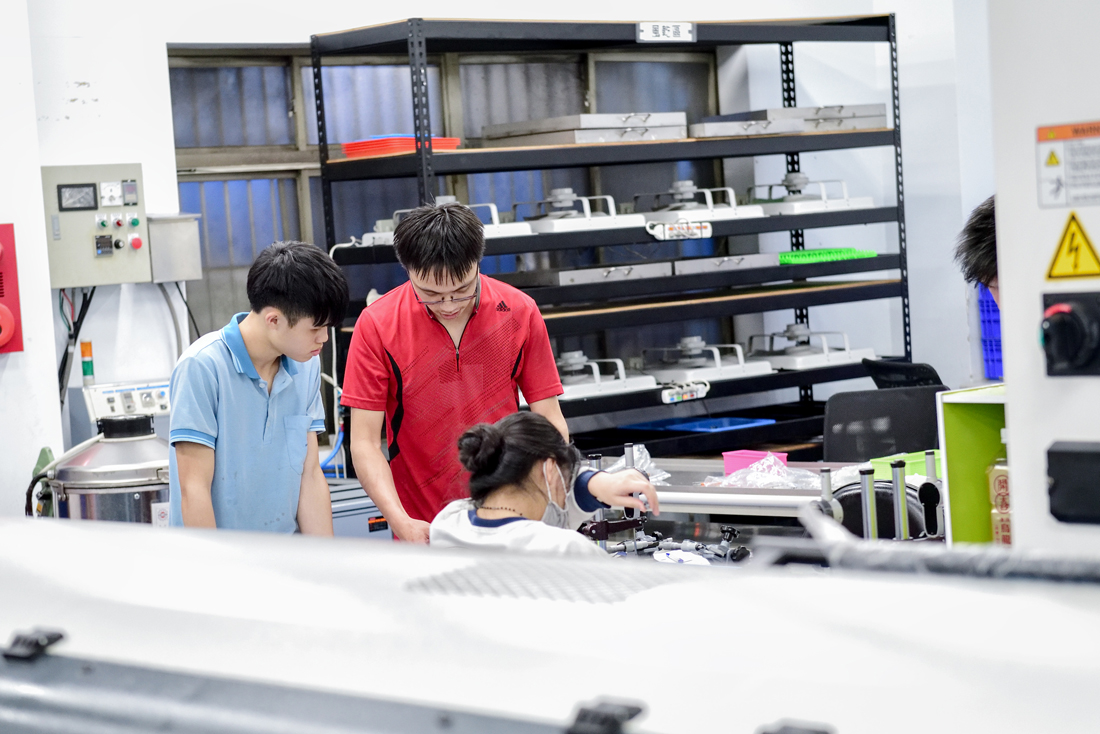

Mega Precision was established by a passionate team who is dedicated to innovation, best-in-class quality and perfect service. Team members are excellent experienced and well educated in the mechanical field. We’re holding certification of ISO 9001 and planning to get IATF 16949 in the near future. Specialized in manufacturing all kinds of turning and milling parts in the applications of pneumatic and liquid valve, engine carburetor, advanced fuel system and automotive OEM products. These industries require rigid quality and delivery standard, also cost sensitive. Equipped with brand new wide range of CNC lathes and high-speed machining centers in house, including DMG-MORI, NOMURA and FANUC. We work closely with professional subcontractors of surface finish to provide full turn-key service as one stop shop. We committed to support customers creating add-value and promote their competitiveness, achieving mutual growth.

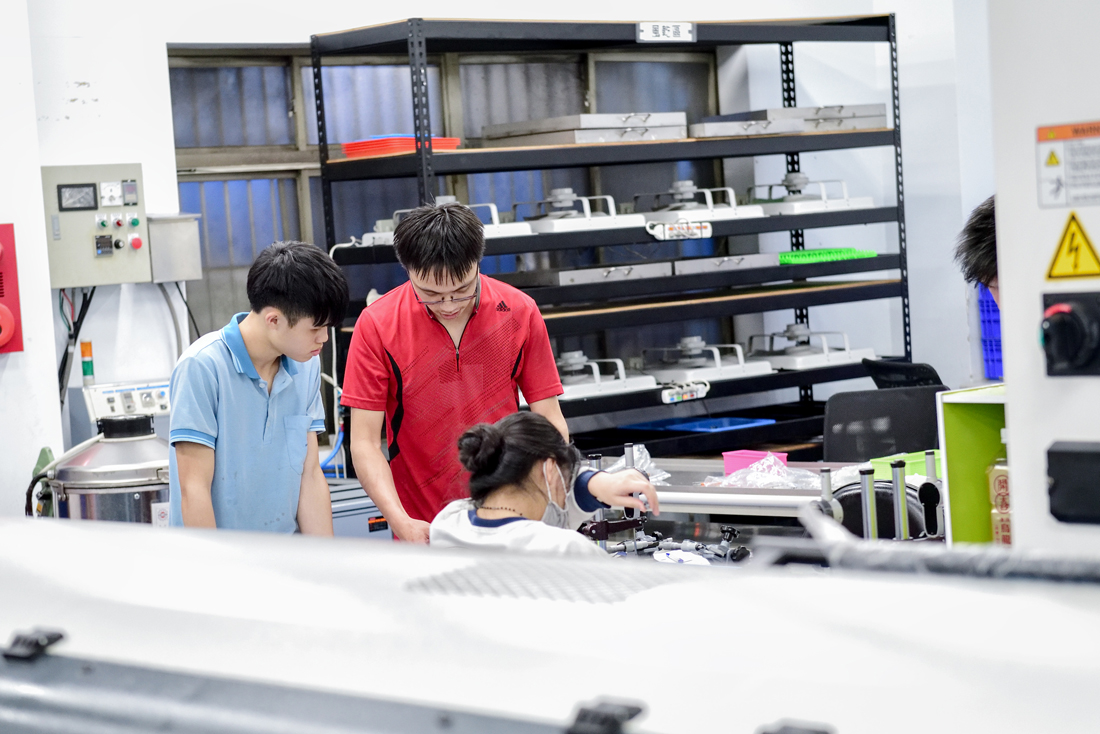

PROFESSION

Engineering Capabilities

Create 2D/3D Models

Mock-up sampling, support to test structure or functional assembly

Chuck and fixture design and fabrication

Capable of extracting all types of 2D/3D format,

like Pro-E, UG, Solidworks and AutoCAD…etc.

Providing qualified documentation complied to ISO 9001.

Capable of making APQP, PPAP, Control Plan, FMEA, CPK Analysis and IMDS

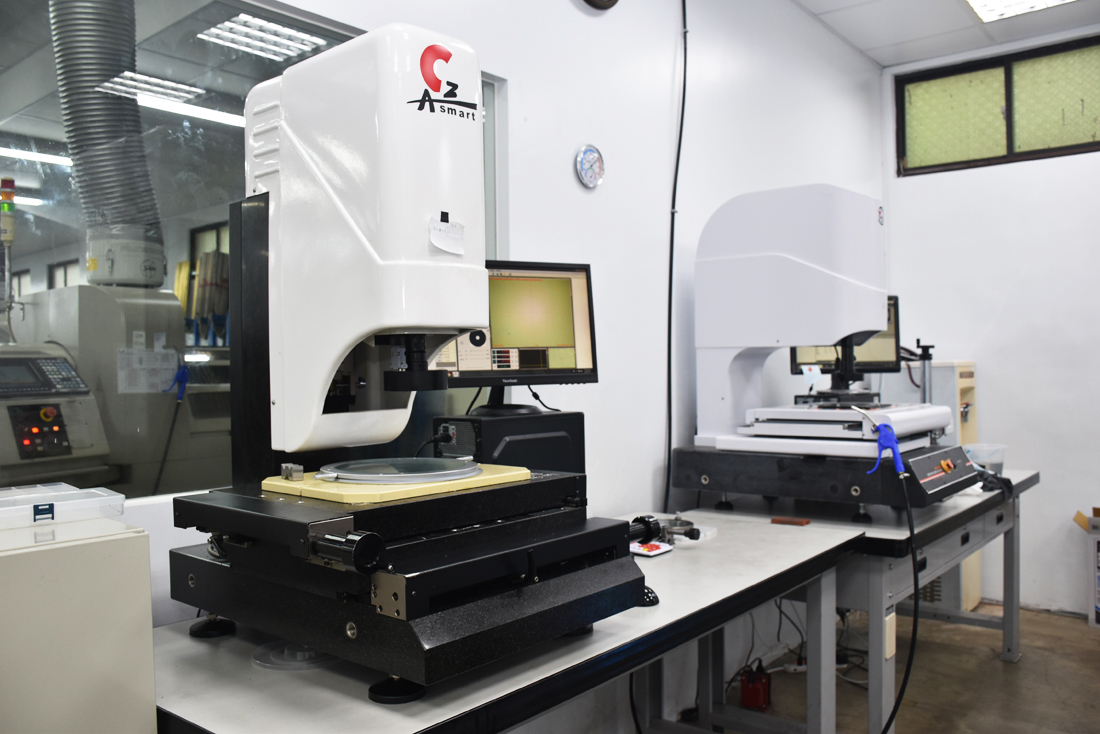

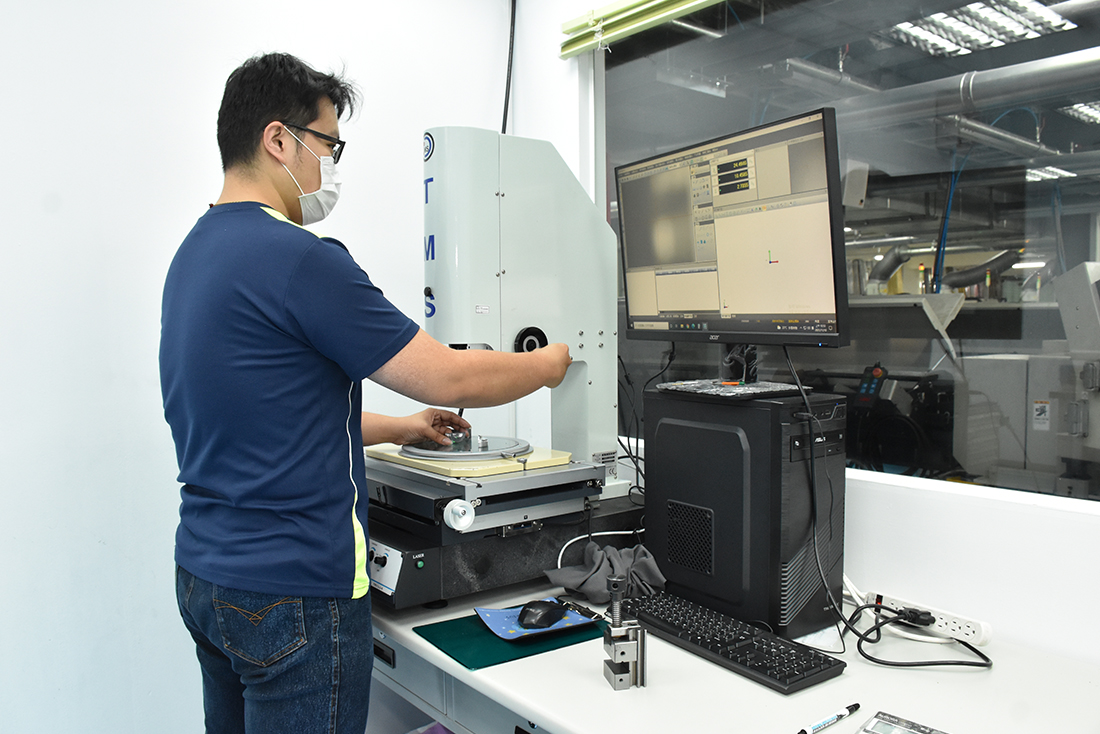

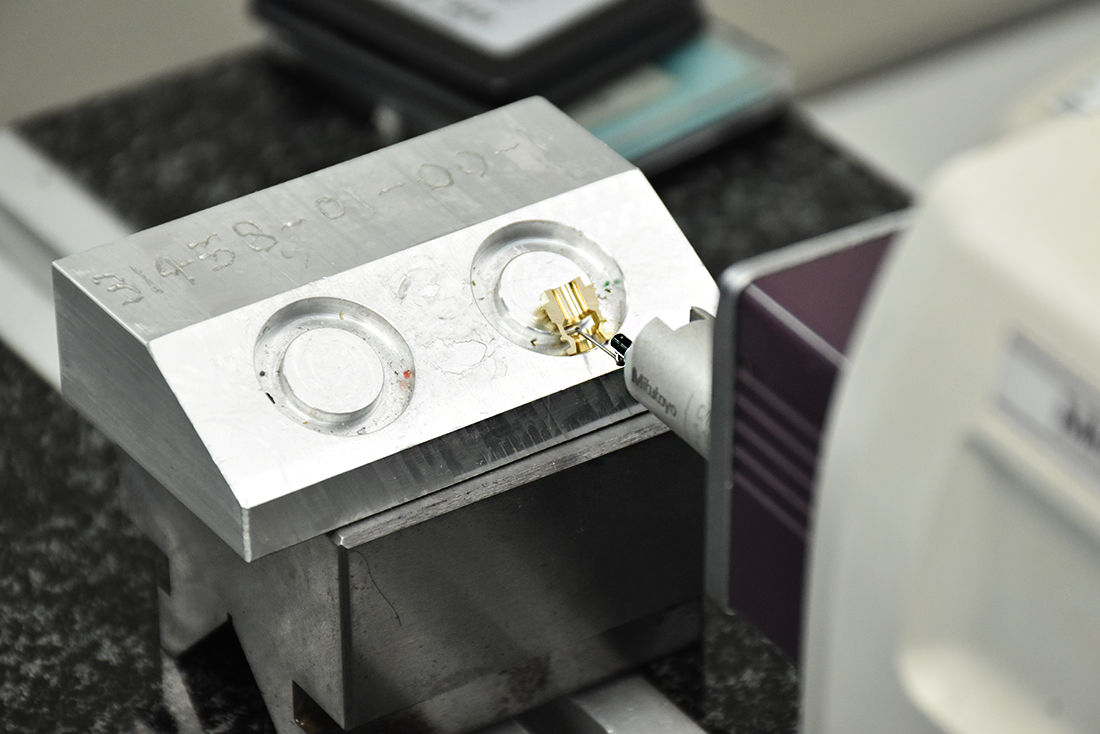

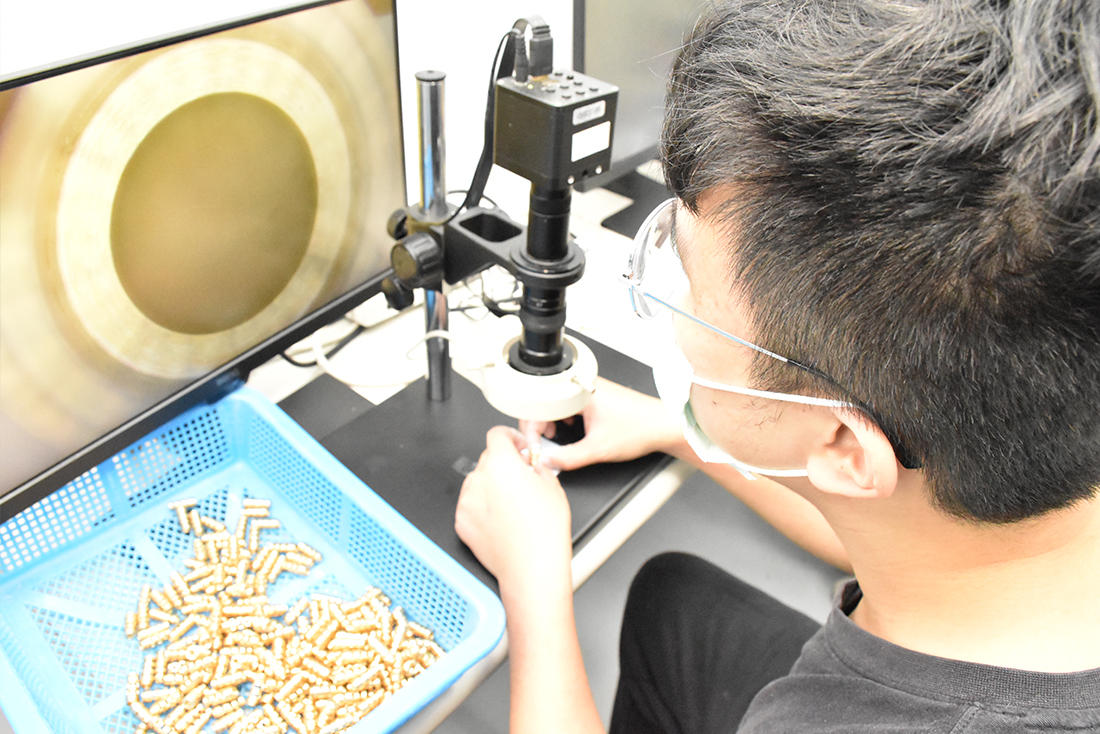

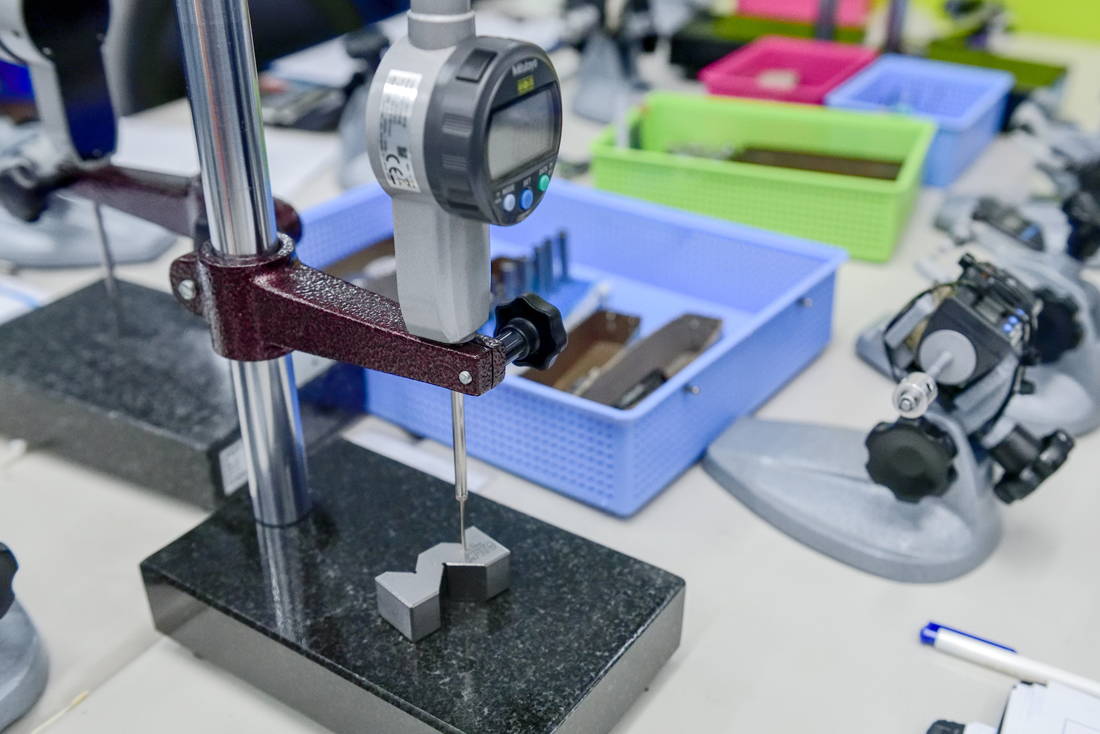

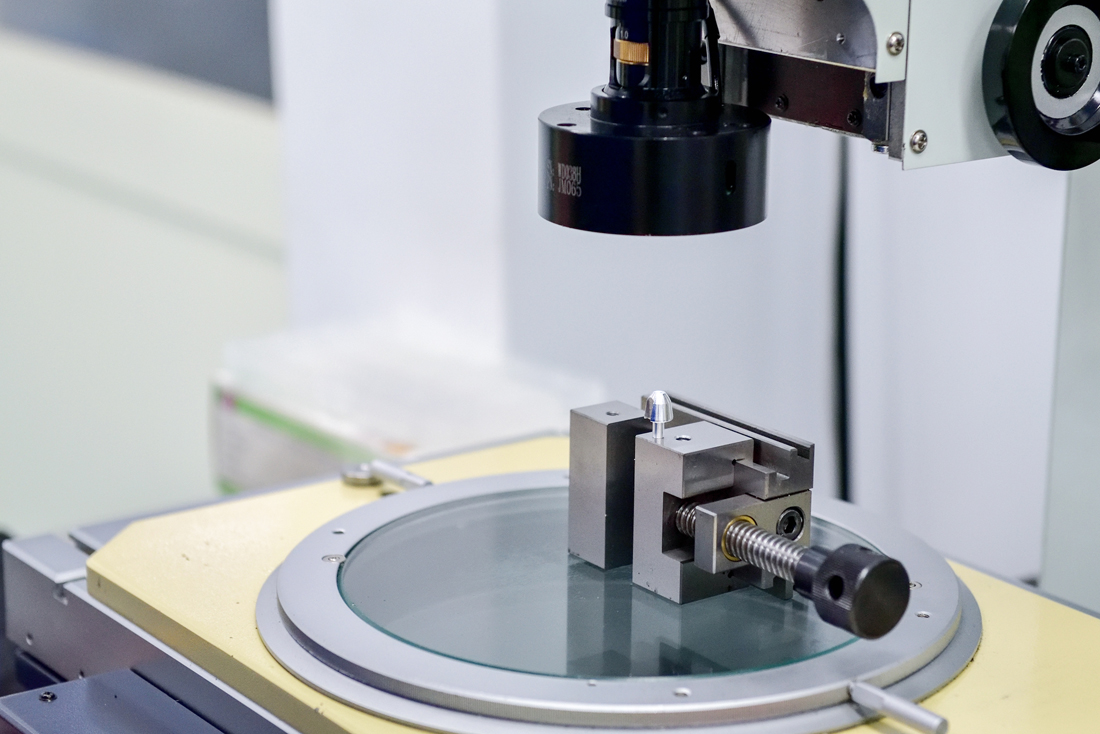

Design and fabricate inspection instruments

Provide engineering solutions in product improvement and cost effectiveness

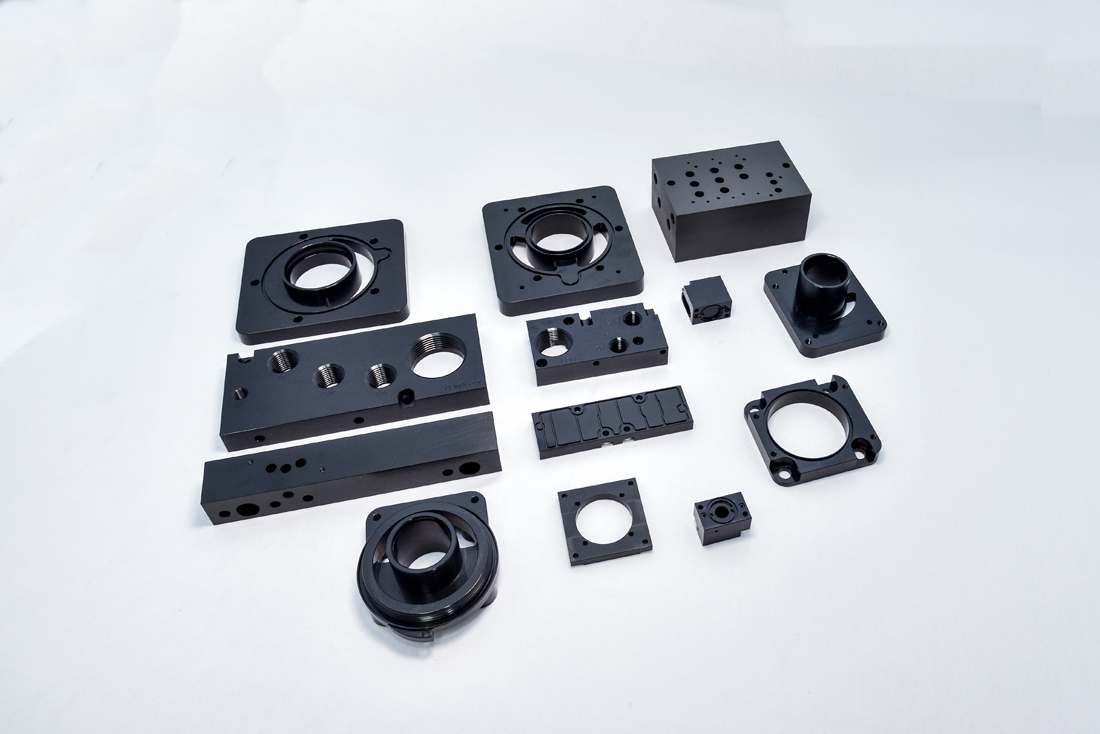

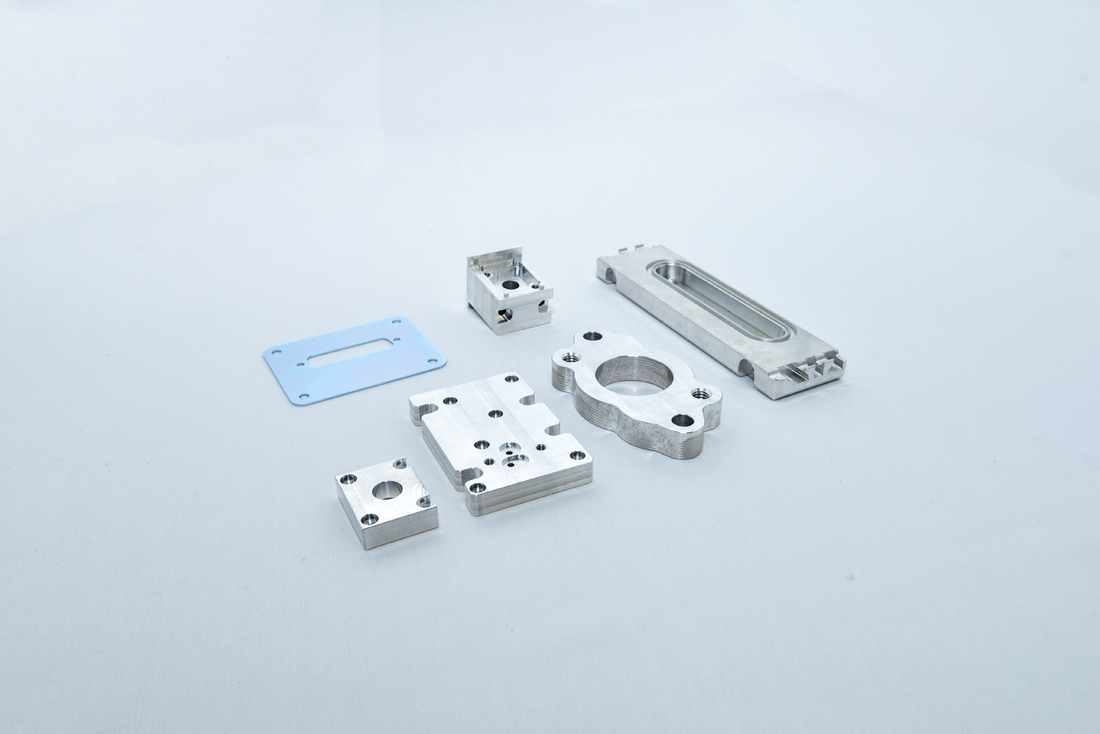

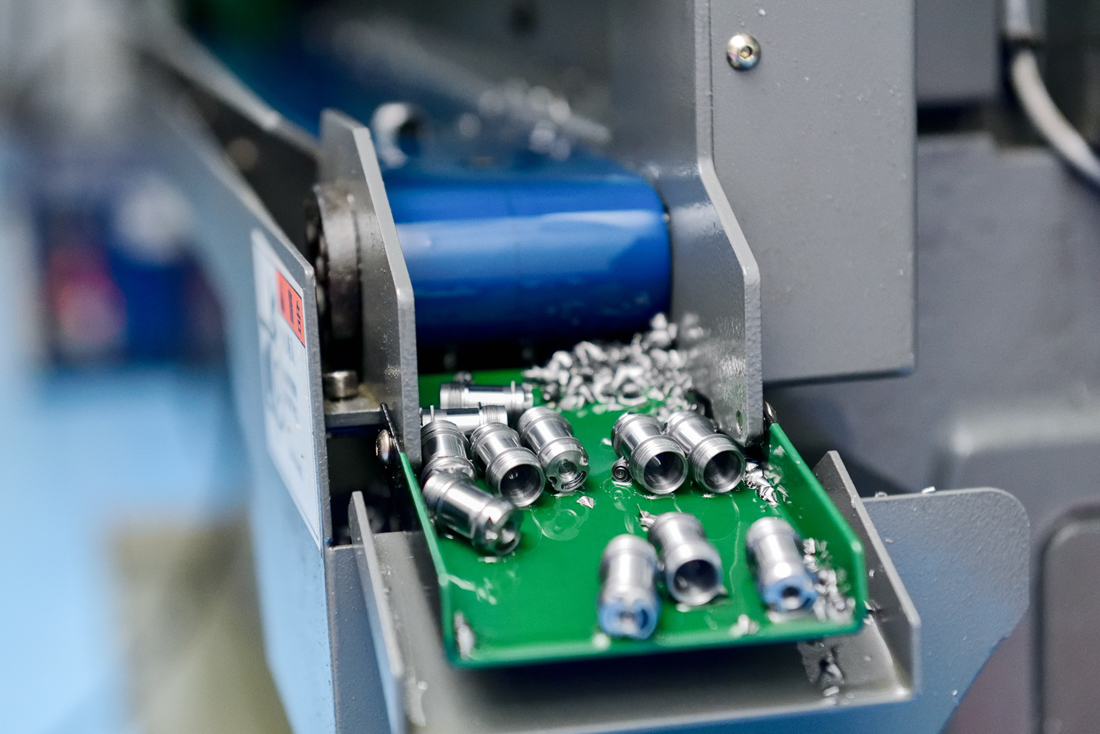

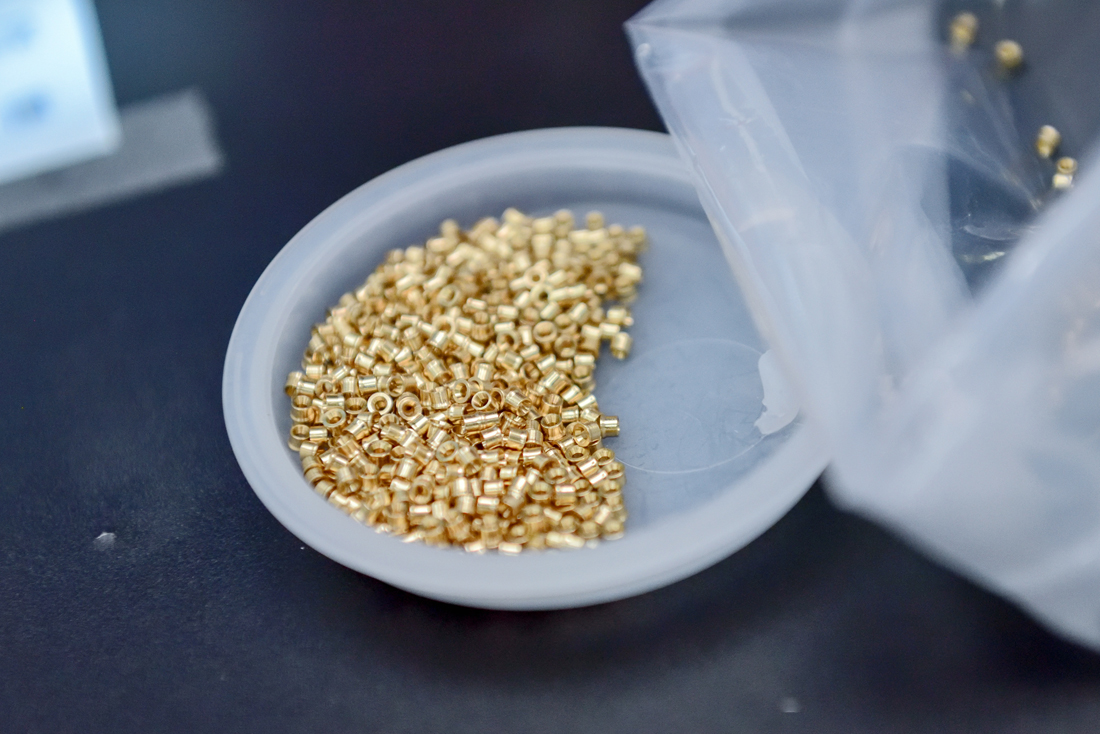

(1) CNC Auto Lathe Parts

(2) CNC High Speed Machining Center Parts (Milling)

(3) Stamping Items

(4) All kinds of metal parts required laser or wire-cut

(1) Mass production flow chart and equipment planning

Provide wide range of surface finish complied to RoHS, including passivate, zinc plating, hyper anneal, electroless nickel plate, anodize, hard anodize, nylon patch, electro-polish

(3) Integrate qualified suppliers to build up quality procedures complied to ISO

(4) Participate suppliers’ quality control and critical features monitoring

(5) Monitor production layout and cost effectiveness consequently, improve production efficiency to lower cost and feedback to customers

Working closely and effectively with overseas’ clients by advanced technologies and software, reply to customers in real time.

Product

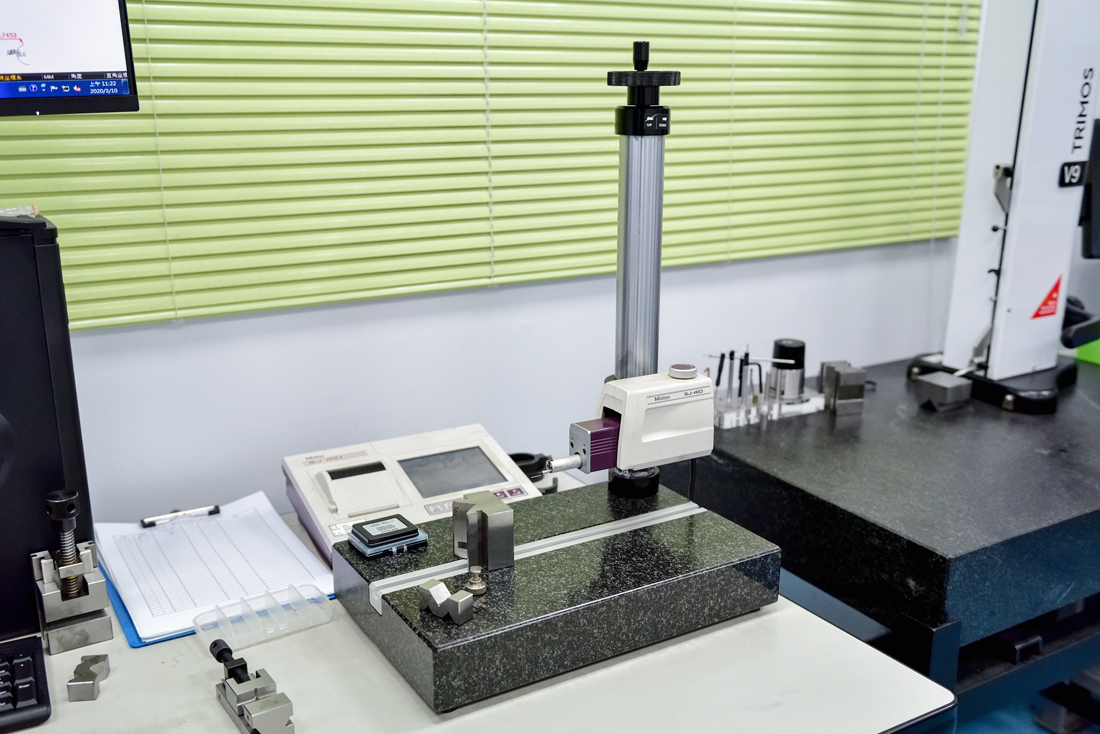

QUALITY GUARANTEE

Our endeavors to total employ involvement and provide zero-complaint service in terms of excellent quality, fast delivery, reasonable price and high-end real time service. We committed to support our customer creating add-value and promote their competitiveness.